Jan. 23, 2025

Received "Award of Excellence" at the Supply Chain Innovation Awards 2023

On July 14, 2023, we received the "Award of Excellence" from the Council for Cooperation among Manufacturing, Distribution, and Sales for the "Efficient Resource Recycling Using Existing Distribution Networks," which was implemented in cooperation with Kirindo Corporation, Kusuri no Aoki Co. Ltd., Miyazaki Corporation, and paper manufacturers, and received the Award of Excellence in the Supply Chain Innovation Awards 2023.

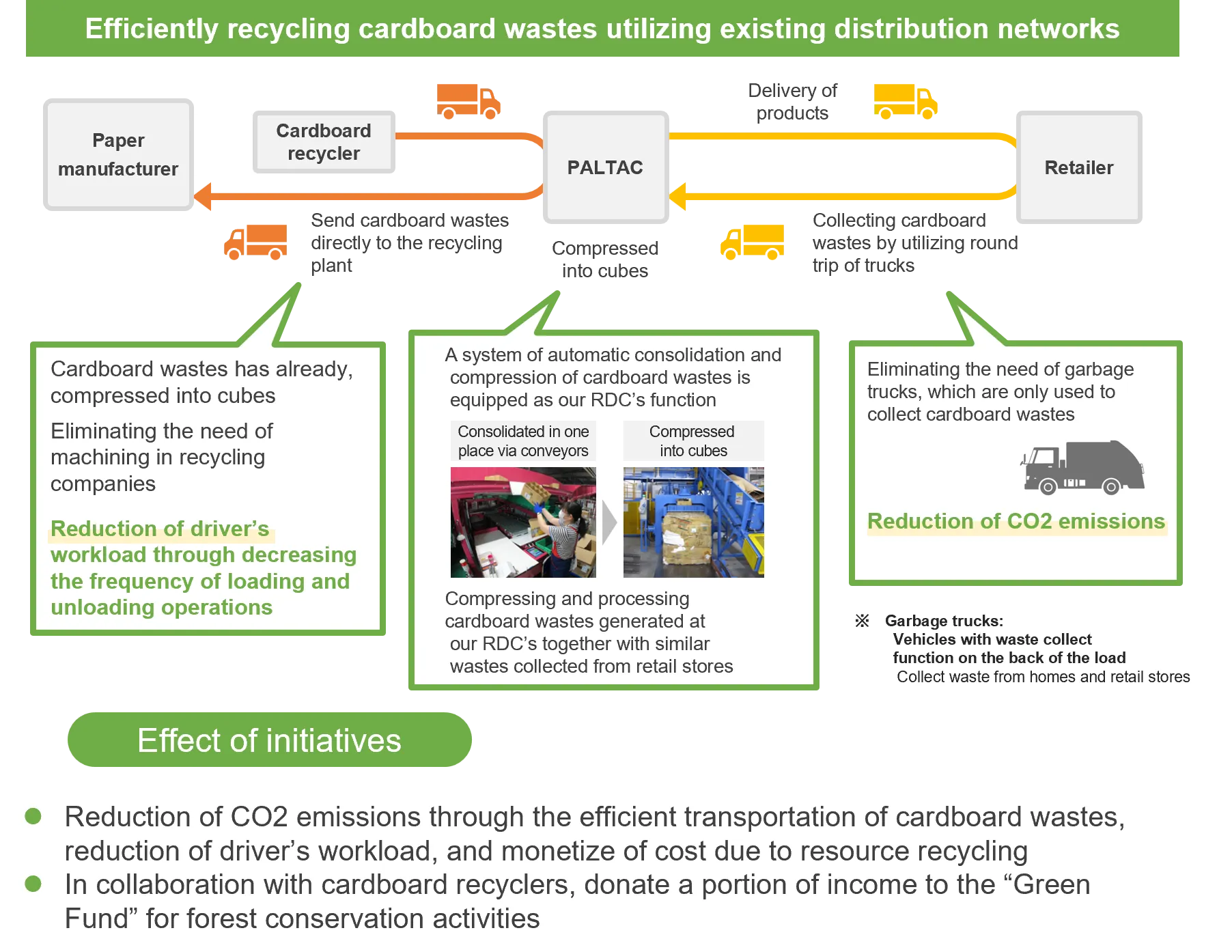

This initiative is to establish a sustainable "resource recycling cycle" that efficiently recycles corrugated cardboard breakage materials by utilizing the existing distribution flow through business activities in cooperation and collaboration with resource recycling companies involved in distribution as well as manufacturing, distribution, and sales.

Specifically, PALTAC collects corrugated cardboard breakables generated by retailers by utilizing the return trips of trucks that have delivered products to the retailers, thereby reducing the number of packer trucks (see note). This system eliminates the need for the recycler to compress and process the materials. These efforts not only improve the loading efficiency of trucks as the volume of cardboard breakers handled increases, but also reduce the number of times cardboard breakers are loaded and unloaded by shipping directly from our company to paper manufacturers, thereby increasing efficiency in the collection and recycling of cardboard breakers, We believe that this is an initiative that will lead to the creation of a sustainable society.

Ltd. and 7 other wholesalers and 58 manufacturers, was awarded the "Excellence Award" in July 2022 in recognition of its efforts to "reduce sales opportunity loss by reducing returns and eliminating inventory bias.

This initiative was based on the joint development of a "store-to-store merchandise transfer system" that utilizes demand forecasting algorithms and other digital technologies to significantly reduce the amount of work and time required to transfer merchandise between stores, thereby realizing the timely and appropriate transfer of merchandise between stores. In terms of delivery, the system has been built into the existing distribution flow, including the use of return delivery services and regular delivery trucks, so that no additional burdens are incurred, and has simultaneously achieved a 30% reduction in returns and increased sales by reducing sales opportunity losses associated with inventory bias.

In July 2021, Sugi Pharmacy, Lion Corporation, and PALTAC were awarded the Grand Prize for their joint efforts to optimize inventory and reduce returns through open collaboration among manufacturing, distribution, and sales.

This initiative addressed the issues of excessive inventories and returned goods, and the three companies transcended their corporate boundaries to reduce waste throughout the supply chain through a "hands-on", "speedy", and "open" cooperative system. Specifically, the three companies shared information on new products, product revisions and discontinuation, sales promotion plans, and delivery volume by store at an early stage, and systematically developed and implemented a solution model of storefront operational measures from launch to end of sales, thereby achieving inventory optimization and reducing returns while expanding sales. The company has also developed and implemented a solution model to reduce inventory optimization and return of goods while expanding sales.