Jan. 23, 2025

Building an industry-leading Far and away the highest best distribution productivity model

The environment surrounding logistics in Japan is changing dramatically in response to the increasing risk that goods will not be able to be transported due to a shrinking working population, climate change, and other factors. In order to realize a sustainable society, it is important to build a "strong," "flexible," and "highly efficient" logistics system by eliminating unreasonable, wasteful act and unevenness in distribution.

PALTAC has long aimed at optimizing and streamlining the entire supply chain, and through the development of a nationwide distribution network and the construction of distribution centers utilizing cutting-edge technology, we have acquired a highly efficient logistics infrastructure and know-how in the intermediate distribution sector. Going forward, PALTAC will continue to innovate on its accumulated strengths to create a logistics model that boasts Far and away the highest best distribution productivity by pursuing even greater efficiency.

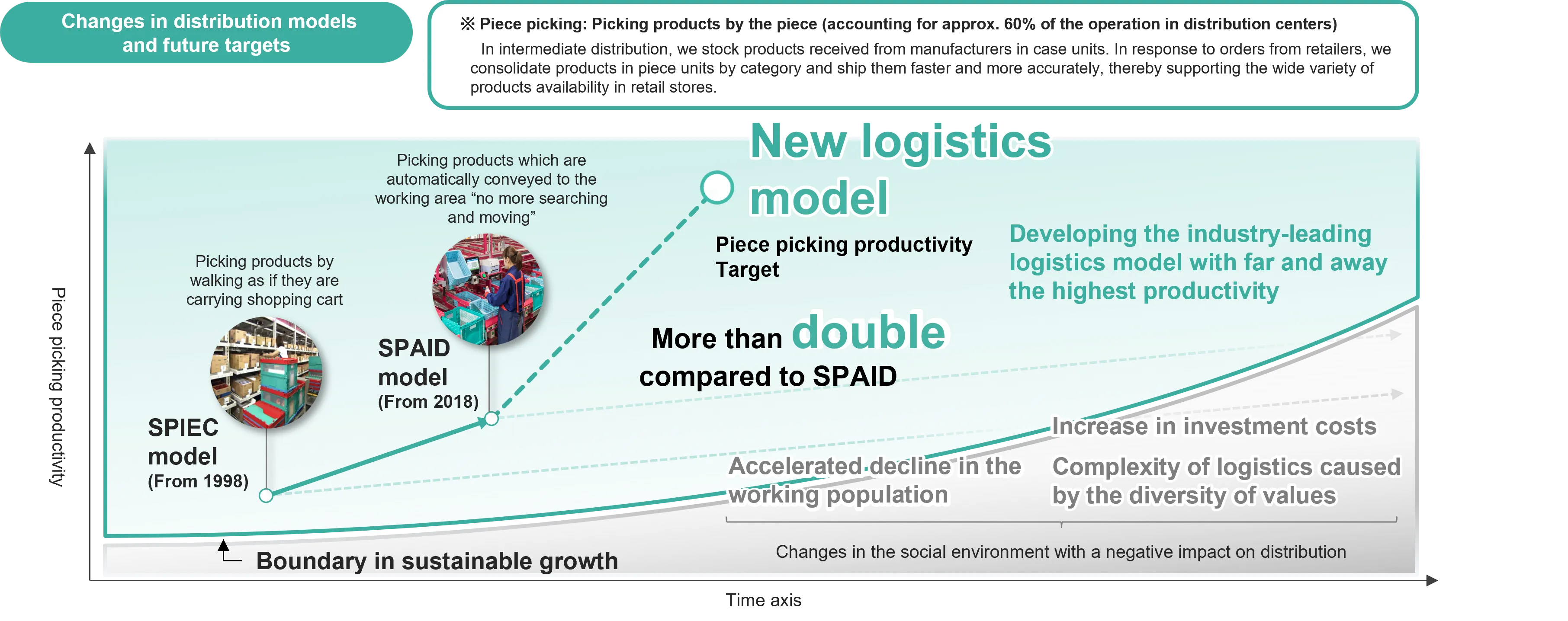

PALTAC is working to build a highly efficient logistics network in order to respond to future changes in the environment and continue sustainable growth. In particular, in the bulk picking (see note) in distribution centers, which plays a particularly important role in intermediate distribution, we have realized faster and more accurate picking operations by making improvements to the SPIEC model since the RDC Kinki started operation in 1998.

Furthermore, in the distribution centers newly built since 2018, the SPAID model, which boasts twice the productivity of the SPIEC model, was developed by combining existing know-how with AI, robotics, and other digital technologies in anticipation of the decline in the working population.

However, in order to cope with changes in a more challenging environment for distribution, such as a declining working population, higher investment costs due to soaring material prices, and increasingly complex logistics operations due to diversifying values, further productivity improvements will be necessary.

To this end, we are taking on the challenge of innovating distribution center operations, targeting productivity that is twice as high as that of the SPAID model, by leveraging the power of our more than 200 professional human resources who "create mechanisms" and the know-how we have cultivated over the years. By doing so, we hope to build the "Far and away the highest best distribution productivity" logistics model that will support the future of distribution and PALTAC's sustainable growth.