Aug. 29, 2023

Notice Concerning Industry-Wide Productivity Improvement through Logistics Digitalization

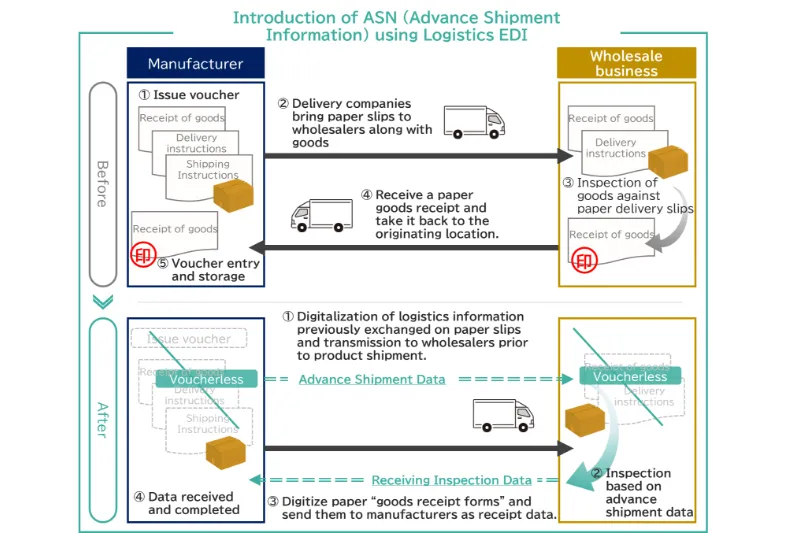

With the aim of solving the 2024 logistics problem and other delivery issues, we have begun full-scale operation of a workflow for receiving goods by introducing Advanced Shipping Notice (hereinafter referred to as ASN) (*2), which utilizes Logistics EDI (*1) provided by Planet Inc.

- EDI (Electronic Data Interchange) is a logistics standard between manufacturers and wholesalers in the daily commodity industry. It is equipped with functions such as the distribution of advance shipment information (ASN) from the manufacturer to the wholesaler and the distribution of "incoming goods receipt inspection data" that provides information on the receipt of goods from the wholesaler to the manufacturer.

- Advance Shipment Information from originating shipper to receiving shipper. It consists of items such as origin code, destination code, order number, product code, and delivery quantity.

With the 2024 logistics problem just around the corner and the industry as a whole faced with the pressing issue of dealing with the driver shortage that affects the stable supply of goods, we have made solving delivery issues one of the key themes of our medium-term management plan and are working to improve delivery efficiency by shortening transport distances and improving loading rates. For example, to reduce the long working hours of our drivers, we have introduced an in-house developed arrival reservation system, which has contributed to the reduction of waiting time.

In the spring of 2020, PlaNet, in cooperation with manufacturers, will begin to study the industry standardization of ASN data specifications and transmission methods, etc. In order to promote this effort industry-wide, PlaNet will hold the "Logistics EDI Promotion Conference" with participating EDI manufacturers and the "Logistics EDI In order to promote this initiative industry-wide, we have been collaborating with the "Logistics EDI Promotion Conference" held by PlaNet with participating EDI manufacturers, the "Study Group on Supply Chain Logistics Productivity" organized by the Institute of Distribution Economics, and the National Federation of Cosmetics and Daily Necessities Wholesalers.

In the verification experiment conducted in June 2023, we were able to reduce our work time associated with "cargo acceptance" by approximately 20% by simplifying inspection work and digitizing paper slips. The introduction of ASN has also eliminated the need to hand over paper slips after goods inspection, thereby reducing the time required for delivery vehicles to enter and exit our distribution center by 40% and further reducing the working hours of our drivers.

Based on the results of the demonstration test, we have already completed the introduction of the system at 10 of our major centers and have begun full-scale operations. In the future, we intend to expand the number of locations where ASN will be introduced to our distribution centers and to encourage manufacturers who have not yet introduced ASN to do so, thereby expanding the benefits of ASN introduction to the entire industry. We will also continue discussions with Planet and manufacturers to further improve operations.

(2) Simplification of inspection work: Reduction of input work after scanning goods upon arrival by obtaining information in advance.

(3) Improved efficiency of warehouse operations: Linkage with receiving reservation system, appropriate personnel allocation, and securing of storage space