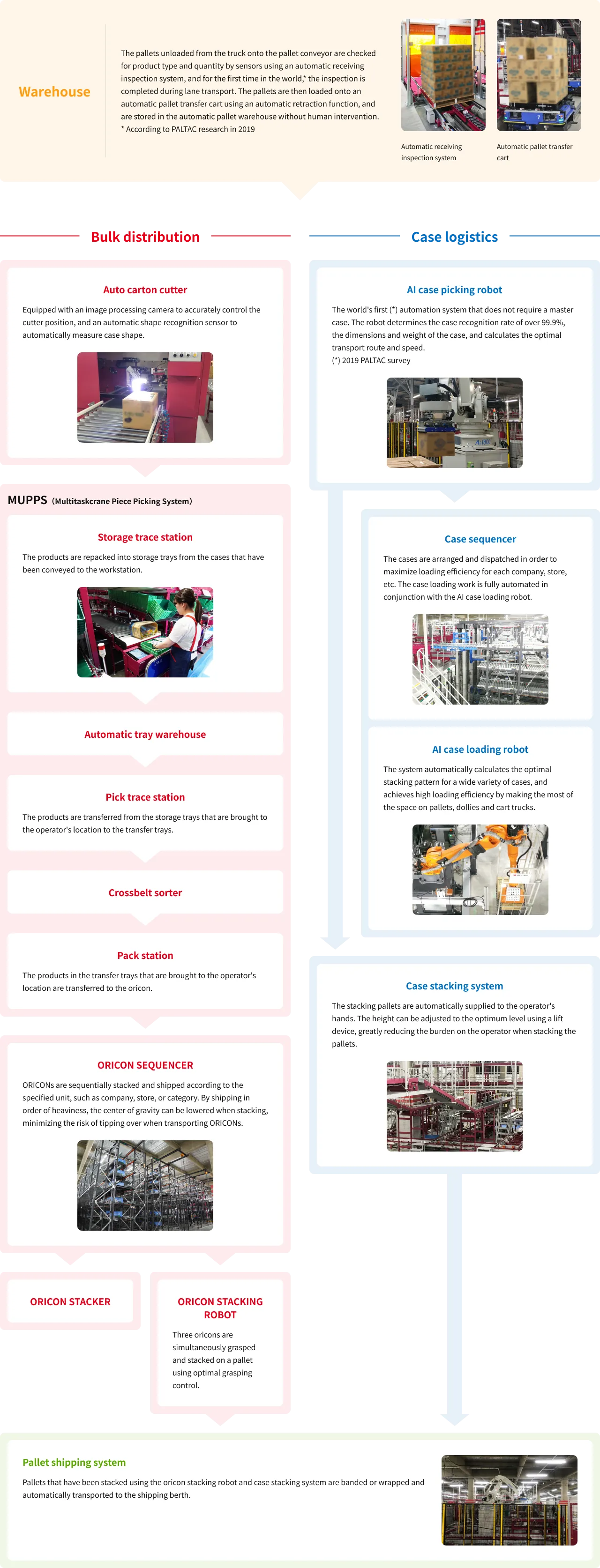

Next generation logistics system "SPAID"

We have introduced the next-generation distribution system “SPAID (Super Productivity Advanced Innovative Distribution)” at RDC Niigata, which began operating in 2018, to achieve automation and high precision in various processes from arrival to shipment.

Since then, RDC Saitama and Tochigi distribution centers have further evolved its functions and capabilities.

SPAID supporting more people-friendly distribution centers

Products move in place of people, picking by robots and people

The figure can be scrolled left and right.

New technologies and functions introduced at the Tochigi Distribution Center

-

DPS (Direct Packing Station)

This is a bulk picking system developed in-house. The system picks only the required number of items from the trays in storage according to the number of orders placed by the stores, and directly packs the items into Oricon packs. This eliminates the need to repackage the required quantity of products from storage trays to pick trays, further improving the overall efficiency of bulk distribution.

-

-

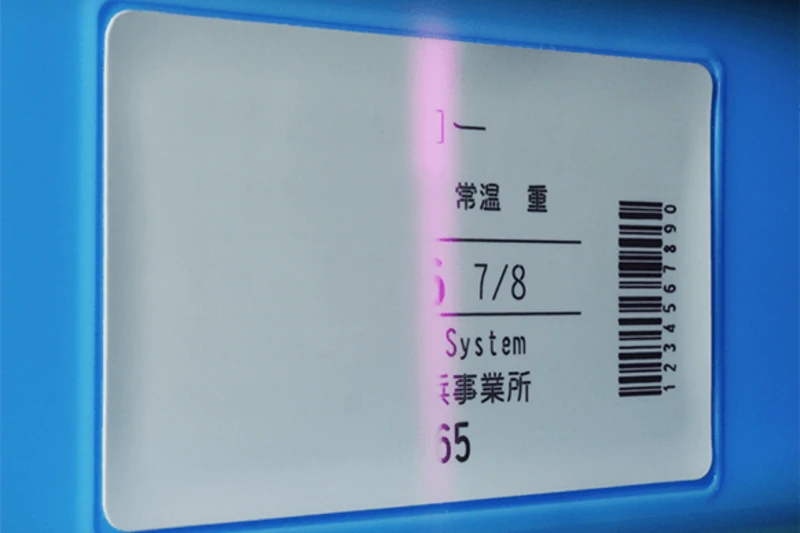

Rewritable labels

This system prints and erases label information using a laser beam. The printed information can be rewritten without human intervention, eliminating mislabeling and forgetting to remove labels, thereby reducing misdelivery, waste, and CO2 emissions.

-

Source: Ricoh Rewritable Laser System Co.

-

AMR (Autonomous Mobile Robot)

Fully automates pallet receiving and shipping with automatic retrieval, automatic payout, and autonomous driving functions in conjunction with an automatic receiving and inspection system. In addition to significantly improving safety by eliminating forklift operations, the self-developed logic determines the optimal transfer source and destination based on facility operating conditions, thereby improving facility efficiency.

-

-

AI case cutting robot

A multi-axis robot is used to cut short sides, long sides, and remove lids, all in a single machine. In addition to expanding the types of cases that can be cut, the accuracy and stability of the cutting position has been improved by using a contact detection system to fix the case before cutting.

-

-

AI Case Picking Robot

In addition to the work, it is also possible to pick from mixed pallets, expanding the range of application to the receiving area.

-

-

Ruptured Material Conveyance System

This is an unmanned magnetic guided vehicle that tows fixtures loaded with broken materials generated by BRS (Bulk Rupture System), etc., and automatically drives approximately 130 m one way to the broken materials warehouse. In addition, it is possible to automatically call a shredding company in front of the shredding warehouse. The machine is designed to run along magnetic tape laid on the floor, and automatically stops if there is an obstacle.

-